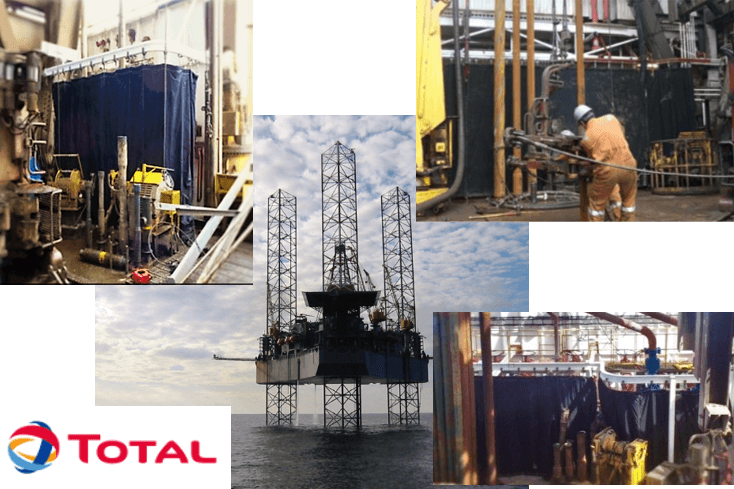

Safety Curtain

How Do the Safety Curtains Work?

The Safety Curtains consist of auxetic fabric which when the load is increased, the stress is absorbed and transferred throughout the fabric. This delivers protection during high pressure testing for personnel, facilities, and other assets within proximity.

Shell Blast Video

Business Case for Safety Curtains on Offshore Rigs by TOTAL S.A.:

Reason Installed on Gorilla V: Time and Cost Savings

1. Two Safety curtains are installed on the drill floor to isolate the stand pipe manifold & 15K choke manifold.

2. Allows high pressure testing on both manifolds while work is performed on the drill floor.

3. The manifolds are on drill floor and are under high pressure right next to the area around the rotary table where drill crew are working therefore work around rotary table is typically stopped during a choke manifold test (i.e. no tripping pipe)

4. The Safety curtains allow the operations to start again as soon as the BOP itself is entirely tested and the test string is out of the hole, because the rest of the choke manifold tests are performed behind them, protecting the crew on the drill floor

5. Time spent testing the manifolds when BOP itself is fully tested is now SAVED.

6. During 6 BOP tests performed on the Rowan Gorilla V, the time taken for the manifold tests performed behind the Safety curtains whilst performing other online activity (i.e. tripping pipe) was recorded to measure the time saved by the curtain

7. Average Cost Savings 117K£ per pressure test.

8. Total potential savings: 900K£ assuming 8 tests.